Workshop and office

This is my workshop and office. It is setup in a tiny room that measure 340cm x 190cm at the floor with a slanted roof. The roof height is 340cm at the high side and 150cm at the low side. So not a lot of space. And since I use it as an office, an electronics lab, a woodworking shop, and a general mechanical workshop, there is a lot of stuff I want to put into it. But many things has to be prioritized away. Setting up an efficient workshop in such a small room is very hard. And my setup is not perfect. But it is pretty functional and might yield some inspiration if you have a tiny room you want to turn into a workshop. Any questions, comments, or ideas are of course welcome.

The main working area

The first pictures is from the working area. It consist of a 346cm x 60cm main workbench and a smaller 80cm x 30cm bench. The main workbench is a hardwood kitchen bench top that I have bolted to the wall and supported with a leg to the floor at the corner that is not connected to any wall. It is also supported at the middle by a slanted strut from the outer edge of the bench and into the wall. This makes it possible to roll the office chair along the full length of the bench without hitting a leg, while still having the bench supported at the middle.

On the small bench I keep various office supplies and any notes or other papers that I might make / need while working. I also have a tiny fridge placed there where I store things like SMT solder paste, my mixed up chemical tin, and other chemicals that likes to be cold. Above the small bench there is a large pegboard where I hang things I like to have quick access to. Or at least that was the plan. It is horribly badly organized as it stays now, and half the things on it is stuff that rather should be at the bottom of a toolbox so I could free up space for more frequently used stuff. One of those days…

On the large bench I have two 60cm x 50cm antistatic mats covering the area that I use for electronics work. And I have two 24″ computer monitors, an ATTEN 8586 hot air rework station, a RIGOL DS1102E digital oscilloscope, a small digital microscope, and a removable vice. Above the bench I have a small shelf and some wall-hung storage containers I use for stuff I want easy access to. On the wall behind the monitors I have mounted some small loudspeakers hooked to the PC, a pick-and-place vacuum pump, a 10-port USB hub, and a digital clock/thermometer.

On the wall between the storage containers and the monitors I have mounted a 6-way power extension to give easy access to power when needed for stuff on the workbench. In the storage containers I keep all the tips and air nozzles for the solder station, nozzles for the pick-and-place pump, accessories for the oscilloscope probes, misc cables for my multimeter, and various other stuff. Above the storage boxes I have placed a paper towel dispenser. Next to the dispenser is another smaller pegboard. Slightly better organized than the large one, but still not good.

Storage

Storage is one of the biggest challenges. A lot of tools, instruments, electronics components, and other bits and pieces are needed to make a useful EE workshop. And if it is to be used for more than just EE work it gets even worse. Most of the bench and shelf space is custom made for the room. But all the commodes and the book shelf are old furniture’s that has been re-purposed.

Peg board, wall storage bins, drawer cabinets, and a large commode

Peg boards are great for keeping frequently used tools. The storage containers and drawer cabinets seen on this picture is mostly used to store mechanical items like screws, nuts, washers, brackets, hinges, etc etc. But also some electronic items like larger connectors, electromechanical items, inductor cores, display modules, etc etc. One of the big drawers in the large commode is full of larger tools (like power tools) while the other is filled with random stuff. Many of the drawers here and elsewhere are filled with plastic containers about the same height as the drawer to make it easier to find stuff even when the drawer is full of totally random stuff.

Shelves with half transparent plastic containers

Drawer cabinets for larger electronic components

Book shelf with assortment box rack.

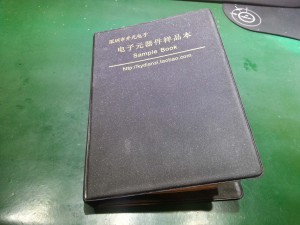

This is where I keep most SMD components. On the top shelf I have several folders that holds all of my 0402, 0603, 0805, 1206 components along with various random “office supplies” and other random stuff.

On the second shelf from top I have a home-built rack that hold 14 assortment boxes that each have 18 small rooms. This is where I store most of my larger SMD components. And also some smaller through-hole components. Compartments containing static-sensitive components are protected with anti-static conductive foam. DIP ICs and PTH MOSFET’s etc have their pins stuck into the foam while SMD ICs that are not in their original tape are sandwiched between two or more layers of foam.

Next to the rack I have 50 small anti-static SMD containers with individual lids that can be connected together in a grid. Those are not used to store components at a permanent basis, but is used when populating a board. After printing out the BOM sorted on component type I will stick as many containers together as there are different components. And then I will put paper tape on each lid and write the component type/value for each there and fill them up with the right amount of each component. This speeds up the manual pick-and-place work a lot compared to hunting around in the whole component library for each component.

Next to those containers you can see my DIY light-box built with high-density cold-white LED strips and multiple layers of glass covered with diffusing film for an even light distribution. I will probably write more about that one somewhere else at some point.

Top shelf

Along the tallest long-wall I have made a 250x40cm shelf from an 18mm plastic laminated wood fiber board. There is very little clearance between this shelf and the door and other obstacles. So it was not possible to support it from the wall alone. It is fixed to two walls with small angle brackets (and one larger bracket) that give good support for three of the four corners, and the fourth corner is supported by a metal rod that is fixed to one of the wood beams inside the roof.

Neat use of space.

Thanks 🙂